How High-Strength Wire Rope Pulling Socks Enhance the Safety and Efficiency of Cable Traction

I. Construction Risks and Industry Pain Points

Cable Abrasion, Breakage, and Uneven Force Distribution Issues

During cable traction operations, cables are prone to abrasion and breakage due to improper handling or excessive force. Additionally, uneven force distribution along the cable can lead to localized stress concentrations, which may compromise the cable's integrity and performance. These issues not only result in costly cable replacements but also pose significant safety hazards to construction personnel.

Limitations of Traditional Traction Methods

Traditional cable traction methods often rely on simple mechanical devices or manual pulling, which lack the precision and control required for modern cable installations. These methods are inefficient, time-consuming, and prone to human error, leading to inconsistent traction forces and increased risks of cable damage. Moreover, they may not be suitable for handling high-tension or large-diameter cables, limiting their applicability in complex engineering projects.

II. Design Philosophy of Wire Rope Pulling Sock

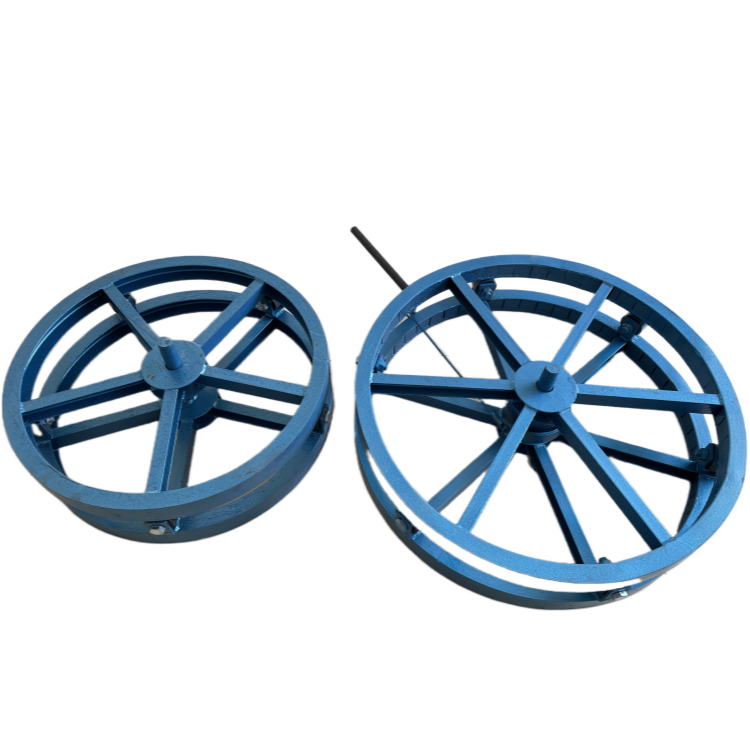

High Tensile Strength Wire Rope

The Wire Rope Pulling Sock is constructed using high-tensile-strength钢丝绳 (wire rope), which provides exceptional strength and durability. This material ensures that the pulling sock can withstand the high forces encountered during cable traction operations without breaking or deforming, thereby protecting the cable from damage.

Adaptive Clamping Effect of the Mesh Structure

The mesh structure of the Wire Rope Pulling Sock offers an adaptive clamping effect on the cable. As the pulling force increases, the mesh tightens around the cable, distributing the force evenly along its length. This self-adjusting mechanism prevents slippage and ensures that the cable remains securely gripped throughout the traction process, enhancing both safety and efficiency.

III. Safety Performance Analysis

Anti-Slip Design

The Wire Rope Pulling Sock incorporates an anti-slip design that prevents the cable from slipping out during traction. The mesh structure, combined with the high-friction surface of the wire rope, creates a strong grip on the cable, ensuring that it remains in place even under high tension. This feature significantly reduces the risk of cable accidents and enhances the overall safety of the traction operation.

Even Force Distribution, Reducing Cable Stress Concentration

By distributing the pulling force evenly along the cable's length, the Wire Rope Pulling Sock minimizes stress concentrations that can lead to cable damage. This even force distribution ensures that the cable is subjected to uniform loading, reducing the likelihood of breakage or deformation. This not only prolongs the cable's service life but also enhances the reliability and performance of the entire cable system.

IV. Efficiency Enhancement

Quick Installation

The Wire Rope Pulling Sock is designed for quick and easy installation. Its simple yet effective design allows construction personnel to attach it to the cable rapidly, reducing setup time and increasing overall efficiency. This feature is particularly beneficial in time-sensitive projects where rapid deployment is crucial.

Reduced Rework

Due to its reliable gripping mechanism and even force distribution, the Wire Rope Pulling Sock minimizes the need for rework caused by cable slippage or damage. This reduces downtime and associated costs, allowing construction teams to focus on completing the project on schedule and within budget.

Improved Construction Progress

By enhancing both safety and efficiency, the Wire Rope Pulling Sock contributes to improved overall construction progress. Its use enables construction teams to complete cable traction operations more quickly and with fewer interruptions, leading to faster project completion times and increased customer satisfaction.

V. Applicable Industries and Engineering Types

Power Engineering

In power engineering projects, the Wire Rope Pulling Sock is ideal for handling high-tension cables used in transmission and distribution lines. Its high strength and reliable gripping mechanism ensure that these critical cables are installed safely and efficiently, minimizing the risk of power outages and ensuring the reliability of the electrical grid.

Communication Engineering

In communication engineering, the Wire Rope Pulling Sock is used for installing fiber optic cables and other communication lines. Its gentle yet secure gripping action protects these delicate cables from damage during traction, ensuring optimal signal transmission and reducing the need for costly repairs or replacements.

Industrial Wiring Projects

In industrial wiring projects, the Wire Rope Pulling Sock is suitable for handling a wide range of cables used in machinery, equipment, and control systems. Its versatility and durability make it an ideal choice for these demanding applications, where reliability and efficiency are paramount.

Source of the article

This article is an original technical manuscript compiled based on practical experience in power and communication engineering construction.

Source: Technical analysis and engineering application summary of wire rope pulling socks.

Source: Technical research materials on cable installation equipment used in power and communication engineering.

Source: Company technical documentation and engineering application experience.

Excerpted from Technical Principles and Engineering Applications of Wire Rope Pulling Socks.