Application and Advantages of Stainless Steel Cable Pulling Socks in Power and Optical Fiber Construction

I. Introduction

In the realms of power and optical fiber construction, cable pulling stands as a pivotal process throughout the entire project. Whether it involves the installation of power cables, the erection of optical fiber communication lines, or the complex wiring within underground conduits, it is essential to accurately and safely pull cables or optical fibers to their designated positions. This process not only tests the technical expertise of the construction team but also heavily relies on the performance of professional tools. Improper selection of pulling tools can easily lead to surface abrasion, internal structural damage to the cables, or even construction safety accidents, resulting in project delays and economic losses.

Cable Wire Rope Socks (stainless steel cable pulling socks, hereinafter referred to as "cable pulling socks") serve as a core auxiliary tool in modern wiring projects. With their unique design and outstanding performance, they have become a "powerful weapon" for solving cable pulling challenges. Through scientific structural design and material selection, they provide comprehensive protection for cables while enhancing construction efficiency and safety, gradually becoming a "standard configuration" in the fields of power and telecommunications engineering.

II. What is a Stainless Steel Cable Pulling Sock (Cable Pulling Sock)

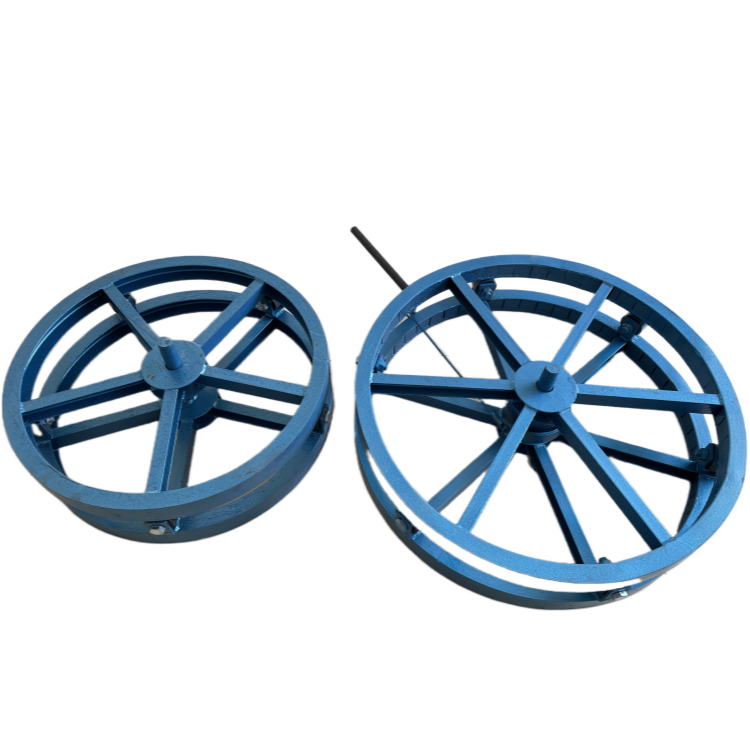

Structural Composition: Steel Wire Rope + Woven Mesh Structure

A cable pulling sock is composed of a high-strength stainless steel wire rope and a precisely woven mesh structure. The steel wire rope, as the core load-bearing component, is made by twisting multiple stainless steel wires together, offering extremely high tensile strength and corrosion resistance. The woven mesh is created through a special process that interlaces the steel wire ropes into a mesh, forming a flexible yet stable wrapping layer that can closely fit the surface of the cable.

Working Principle: Uniform Force Distribution and Prevention of Cable Damage

During the pulling process, the cable pulling sock generates friction against the cable surface through the woven mesh, evenly distributing the pulling force across the entire cable and preventing local stress concentration that could cause damage. Meanwhile, the flexible structure of the sock can adapt to the bending and twisting of the cable, reducing internal structural damage caused by forced straightening. Additionally, the wear-resistant nature of the stainless steel material ensures that the sock remains durable and less prone to wear during long-term use, further extending its service life.

III. Analysis of Core Advantages

High-Strength Stainless Steel Material: Dual Guarantee of Durability and Reliability

The stainless steel material endows the cable pulling sock with excellent tensile strength and corrosion resistance. In power construction, cables may need to pass through harsh environments such as damp or salt-spray conditions. Ordinary material pulling tools are prone to corrosion and breakage, leading to construction interruptions. In contrast, stainless steel socks can resist chemical corrosion and oxidation, maintaining stable performance even in extreme environments and significantly reducing the frequency of tool replacement and maintenance costs.

Stable Pulling Force Provided by the Woven Mesh Structure: Precise Control and Safety Protection

The woven mesh structure, through its multi-directional interlacing design, evenly transmits the pulling force to the cable surface, preventing cable deformation or breakage caused by single-point force application. For example, in optical fiber construction, optical fibers are extremely sensitive to bending radius. The flexible wrapping of the cable pulling sock can effectively control the pulling angle, preventing signal attenuation due to excessive bending of the optical fiber. Moreover, the elastic design of the sock can also absorb some of the impact force, providing additional safety buffers for the construction.

Safety, Efficiency, and Construction-Friendliness: Comprehensive Enhancement of Project Value

Safety: By reducing the risk of cable damage, cable pulling socks lower the incidence of construction accidents, ensuring the safety of personnel and equipment.

Efficiency: Their lightweight design and ease of operation enable construction personnel to quickly install and remove them, shortening the time required for each pulling operation.

Construction-Friendliness: The universal design of the socks supports the pulling of cables of various specifications, eliminating the need for frequent tool changes and simplifying the construction process.

IV. Typical Application Scenarios

Power Cable Installation

In the laying of high-voltage cables, cable pulling socks can replace traditional pulling ropes to prevent scratches on the cable surface and damage to the insulation layer. For instance, when crossing underground conduits or overhead lines, the flexible structure of the sock can adapt to complex paths, ensuring the safe arrival of the cable at its destination.

Optical Fiber Communication Construction

Optical fibers are highly sensitive to pulling force and bending radius. Cable pulling socks, through uniform force distribution and angle control, prevent signal attenuation caused by excessive stretching or bending of the optical fiber. In long-distance optical fiber laying, the durability of the sock also reduces the number of tool changes during the process, enhancing construction continuity.

Underground Conduit Wiring

In narrow underground conduits, cable pulling needs to overcome friction and spatial constraints. The compact design and high friction characteristics of cable pulling socks can reduce pulling resistance while protecting the cable from scratches caused by conduit edges, ensuring wiring quality.

V. Conclusion

Stainless steel cable pulling socks, with their high-strength material, scientific structural design, and multiple advantages, have become an ideal choice for cable pulling in power and telecommunications engineering. They not only solve problems such as cable damage and low efficiency associated with traditional pulling tools but also enhance construction safety and reliability, providing solid guarantees for project quality and progress. As power and optical fiber construction advance towards intelligence and refinement, the application value of cable pulling socks will become even more prominent, serving as a key tool driving technological progress in the industry.

Article Source: This article is written based on a comprehensive synthesis of technical practices and industry research materials in the fields of power and telecommunications engineering.