Fiberglass Conduit Rods Competent Helper in Cable Installation

I. Introduction

Current Situation and Development Trends of the Cable Installation Industry

In the modern era of rapid technological advancement, the cable installation industry serves as a crucial foundation for infrastructure construction and the operation of various electronic devices. With the acceleration of urbanization and the continuous expansion of fields such as communication and power, the demand for cable installation is on the rise, and the requirements for installation quality and efficiency are becoming increasingly stringent.

From traditional indoor wiring to complex outdoor underground laying and high-speed communication network construction, the scenarios for cable installation are becoming more diverse. This has prompted the industry to constantly explore higher-quality and more efficient installation materials and methods.

The Key Position of Fiberglass Conduit Rods in Cable Installation

Against this backdrop, fiberglass conduit rods have emerged as a standout in the cable installation field due to their unique performance advantages. They have gradually occupied a key position, providing reliable physical support for cable installation.

II. The Source of Charm of Fiberglass Conduit Rods - Characteristic Analysis

Physical Characteristics

High Strength: Fiberglass conduit rods are capable of withstanding relatively large tensile and compressive forces, making them less prone to breakage. This high-strength property ensures that they can firmly support cables during installation, even under significant external forces. For example, in large-scale industrial building cable installations, where cables may be subjected to heavy loads and mechanical stresses, fiberglass conduit rods can maintain their integrity and prevent cable damage.

Flexibility: They can be bent, allowing them to adapt to conduits of different shapes and curved paths. In complex building structures, where conduits often have numerous bends and turns, the flexibility of fiberglass conduit rods enables them to navigate through these obstacles smoothly, facilitating the cable installation process.

Corrosion Resistance: Fiberglass conduit rods can maintain good performance in humid and chemically corrosive environments. In outdoor underground cable installations, where the rods may be exposed to moisture, soil chemicals, and other corrosive substances, their corrosion resistance ensures long-term stability and reliability, reducing the need for frequent maintenance and replacement.

Electrical Characteristics

Insulation Performance: They effectively prevent electrical faults such as short circuits during cable installation. By providing an insulating barrier between the cable and the surrounding environment, fiberglass conduit rods enhance the safety of the installation process and the overall electrical system. For instance, in power cable installations, this insulation property is crucial for preventing electrical accidents and ensuring the normal operation of the power grid.

Low Electrical Conductivity: Fiberglass conduit rods reduce interference with cable signals. In communication cable installations, especially for high-speed data transmission systems like fiber optic cables, any signal interference can lead to data loss or degradation. The low electrical conductivity of fiberglass conduit rods helps maintain the integrity of the signals, ensuring reliable and high-quality data transmission.

III. Unveiling the Types and Specifications of Fiberglass Conduit Rods

Type Classification

Based on Diameter Size: They are divided into different specifications such as thin rods, medium rods, and thick rods. Thin rods are suitable for installing relatively light and small-diameter cables, while thick rods are used for heavier and larger-diameter cables. This classification allows for a more precise match between the conduit rod and the cable, optimizing the installation process.

Based on Length: They are categorized into short rods and long rods to meet different installation distance requirements. Short rods are convenient for short-distance installations within a limited space, such as in small rooms or equipment cabinets. Long rods, on the other hand, are ideal for long-distance cable installations, such as in large buildings or outdoor underground conduits.

Specification Selection Guide

Diameter Selection: Choose the appropriate diameter of the conduit rod based on the diameter and weight of the cable. Using a rod with an insufficient diameter may result in the rod breaking under the weight of the cable, while an overly thick rod may be difficult to maneuver through the conduit. For example, when installing a bundle of thin communication cables, a thin fiberglass conduit rod is sufficient, whereas for heavy-duty power cables, a thicker rod is required.

Length Selection: Select the suitable length of the conduit rod according to the length and complexity of the installation path. In a straight and short installation path, a short rod can be used, while in a long and winding path, a long rod or a combination of multiple rods connected by joints is necessary.

Case Study on Improper Specification Selection: In a certain outdoor underground cable installation project, the installation team used short and thin fiberglass conduit rods for a long and complex conduit system. As a result, the rods were unable to reach the end of the conduit, and multiple joints were required. However, the joints were not properly connected, leading to the rods getting stuck in the conduit during the cable traction process. This not only delayed the project schedule but also caused damage to the cables and conduits, resulting in additional costs for repairs and replacements.

IV. The Brilliant Applications of Fiberglass Conduit Rods in Cable Installation

Indoor Cable Wiring

Cable Laying in Building Walls and Ceilings: Fiberglass conduit rods are widely used for cable laying in the interior of buildings. Their flexibility allows them to be easily inserted into narrow conduits hidden within walls and ceilings. For example, in office buildings, where a large number of communication and power cables need to be installed, fiberglass conduit rods can navigate through the complex network of conduits, ensuring a neat and organized cable layout.

Navigating Narrow Pipes and Corners: They demonstrate their advantages when passing through narrow pipes and corners. In residential buildings, where the space for cable installation is often limited, fiberglass conduit rods can be bent and manipulated to pass through tight bends and small-diameter pipes, making the installation process more efficient and reducing the need for extensive conduit modification.

Outdoor Underground Cable Laying

Cable Traction in Underground Conduits: Fiberglass conduit rods play a vital role in cable traction in underground conduits. Their high strength enables them to withstand the pulling force applied during the cable installation process, ensuring that the cables are smoothly pulled through the conduits. For example, in urban underground power cable laying projects, fiberglass conduit rods can effectively pull heavy power cables over long distances, improving the installation efficiency.

Advantages in Dealing with Complex Underground Geological Conditions and Obstacles: In outdoor underground environments, there are often various geological conditions and obstacles such as rocks, tree roots, and old underground infrastructure. Fiberglass conduit rods, with their flexibility and strength, can adapt to these complex conditions and navigate around obstacles, reducing the difficulty of cable installation and minimizing the impact on the surrounding environment.

Communication Network Construction

Application in Fiber Optic Cable Installation: Fiberglass conduit rods are extensively used in the installation of fiber optic cables, which are the backbone of modern high-speed communication networks. Their low electrical conductivity and insulation performance are essential for protecting the delicate fiber optic cables from electrical interference and damage during installation.

Importance for Ensuring High-Speed Data Transmission: In today's information age, high-speed data transmission is crucial for various applications such as internet access, video streaming, and cloud computing. Fiberglass conduit rods help maintain the integrity of the fiber optic cables, ensuring that data can be transmitted at high speeds without signal loss or degradation, thus supporting the smooth operation of communication networks.

V. The "Good Partners" of Fiberglass Conduit Rods - Related Accessories and Equipment

Accessory Introduction

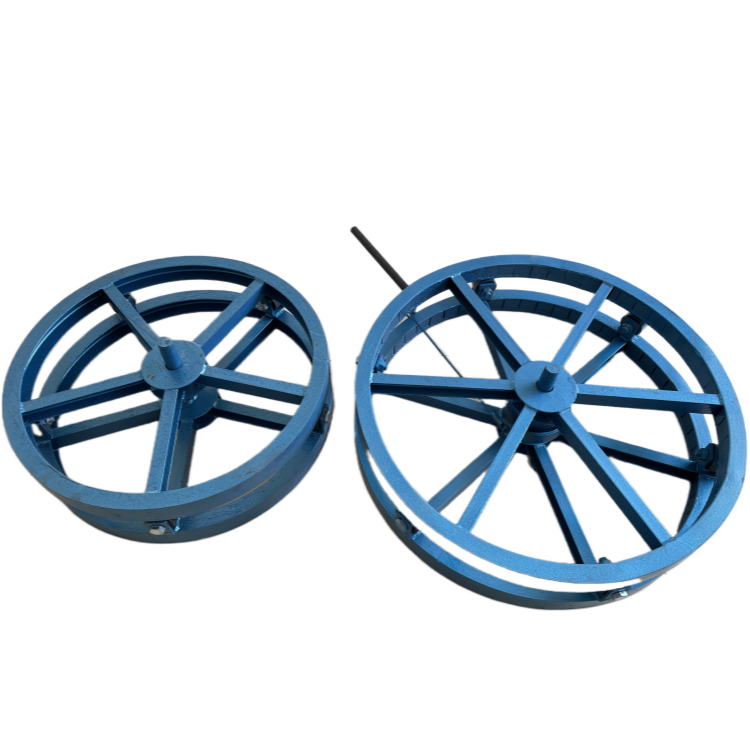

Conduit Rod Joints: These are used to connect conduit rods of different lengths, extending their usable length. In long-distance cable installations, where a single rod may not be long enough, joints allow for the combination of multiple rods to form a continuous and stable conduit system. For example, in a large-scale industrial park cable installation project, conduit rod joints are used to connect several long rods, enabling the cables to be pulled through the entire park's underground conduit network.

Guide Heads: Installed at the front end of the conduit rod, guide heads help the rod pass through the conduit smoothly. They have a streamlined shape that reduces friction and prevents the rod from getting stuck in the conduit. In complex conduit systems with multiple bends and turns, guide heads play a crucial role in ensuring the successful installation of the conduit rod and the subsequent cable.

Other Accessories: Protective sleeves are used to protect the conduit rod from damage during installation, especially when passing through rough or sharp-edged conduits. Marking rings are attached to the conduit rod to identify different sections or cables, facilitating the installation and maintenance process. For example, in a multi-cable installation project, marking rings can be used to distinguish between power cables and communication cables, making it easier for technicians to manage and troubleshoot the system.

Cooperating Equipment

Conduit Threading Machines: These machines work in conjunction with fiberglass conduit rods to improve the threading efficiency. They provide a controlled and continuous pulling force, enabling the conduit rod to be quickly and accurately inserted into the conduit. In large-scale cable installation projects, conduit threading machines can significantly reduce the labor intensity and installation time, improving overall project efficiency.

Cable Traction Machines: Cable traction machines are used to provide powerful traction for cable installation. When combined with fiberglass conduit rods, they can pull heavy cables through long and complex conduits. The traction force can be adjusted according to the cable type and installation conditions, ensuring a safe and efficient installation process. For example, in high-voltage power cable installation projects, cable traction machines are essential for pulling the heavy cables over long distances, while the fiberglass conduit rods guide and support the cables within the conduit.

Synergistic Working Principles: The conduit threading machine first inserts the fiberglass conduit rod into the conduit, and then the cable is attached to the end of the rod. The cable traction machine then applies a pulling force to the cable, which is transmitted through the conduit rod. The guide heads on the rod help it navigate through the conduit, while the joints allow for the extension of the rod if necessary. This coordinated operation between the equipment and the conduit rod ensures a smooth and efficient cable installation process.

VI. Purchase and Usage Precautions for Fiberglass Conudit Rods

Purchase Points

Choose Products from Regular Manufacturers: Selecting products from regular manufacturers ensures reliable quality. Regular manufacturers have strict quality control systems and production standards, which can guarantee that the fiberglass conduit rods meet the relevant industry specifications and performance requirements. For example, products from well-known manufacturers are more likely to have consistent material quality and dimensional accuracy, reducing the risk of installation failures.

Check Product Test Reports and Certification Certificates: Before purchasing, it is essential to check the product's test reports and certification certificates. These documents provide evidence of the product's quality and compliance with relevant standards. For instance, test reports can show the rod's strength, flexibility, and electrical properties, while certification certificates from authoritative organizations indicate that the product has passed specific quality and safety assessments.

Consider Price Factors, but Do Not Only Pursue Low Prices and Ignore Quality: While price is an important consideration, it should not be the sole determining factor. Low-priced products may be of inferior quality, which can lead to problems during installation and use, such as breakage, poor performance, and short service life. It is advisable to balance price and quality, choosing products that offer good value for money and can meet the long-term requirements of the cable installation project.

Usage Precautions

Check the Conduit Rods and Accessories for Damage Before Operation: Before starting the installation process, carefully inspect the fiberglass conduit rods and all related accessories for any signs of damage, such as cracks, breaks, or deformation. Damaged components should not be used, as they may fail during installation, causing delays and potential safety hazards.

Use According to the Correct Operating Methods and Avoid Excessive Force or Illegal Operations: Follow the manufacturer's instructions and industry best practices when using fiberglass conduit rods. Avoid applying excessive force during insertion, pulling, or bending, as this can damage the rods or the cables. Illegal operations, such as using the rods for purposes other than intended or ignoring safety warnings, should also be strictly avoided.

Pay Attention to Safety during Use and Wear Necessary Protective Equipment: Cable installation work may involve certain risks, such as electrical shock, falling objects, and sharp edges. Therefore, it is crucial to wear appropriate protective equipment, such as safety gloves, goggles, and helmets, during the installation process. Additionally, follow safety procedures and regulations to ensure the well-being of the installation personnel and the success of the project.

References

This article draws on information from industry reports on cable installation, technical specifications of fiberglass conduit rod manufacturers, and practical case studies in the field of cable engineering. Specific sources include industry research institutions' publications, product manuals from leading fiberglass conduit rod suppliers, and project reports from cable installation companies.